A warehouse used for storage of medicine, chemicals, food items, electronics etc. are under controlled conditions of temperature & humidity. In many of these cases, it is required to record and monitor the temperature and humidity to meet regulatory requirements and internal quality assurance procedures.

What are the requirements for a warehouse monitoring system?

Inside a warehouse, generally the following parameters need to be monitored:

- The temperature of the warehouse has to be recorded and monitored. Depending on the size and shape of the area, you may need to use multiple sensors inside the warehouse. If you are using the area for storage of medicines, the locations of the sensors of the warehouse monitoring system are decided after conducting a temperature mapping study.

- The humidity of the area also needs to be recorded and monitored based on the type of goods being stored and the humidity conditions of the location. Generally for items such as medicine, chemicals, tobacco etc., humidity also is important and hence need to be recorded and monitored.

- Power failure needs to be critically monitored. In the case of power failure especially after working hours, the operators need to be alerted so that proper action can be taken on time.

How to select a suitable warehouse temperature monitoring system?

While selecting a temperature and humidity warehouse monitoring system, you have to consider the following aspects.

- It is preferred to use a wireless system (Radio frequency or Zigbee) which does not require a power supply. You may have to install the sensors at inaccessible places and pulling a power line and an Ethernet cable will be practically difficult.

- Also, a wireless remote monitoring system is preferred because you will have pallets and boxes being loaded using a forklift and should never touch a wire which will cause damages.

- You may need to rearrange the sensors depending on the hot and cold points inside the area. In case the sensors are wired, it will be extremely difficult to change the locations at a later date.

- The battery life of the sensors should be 8 to 12 months so that it does not require frequent recharging. The batteries should be preferably rechargeable type.

- The warehouse remote monitoring system should generate Email or SMS alerts if the battery is low or if there is a problem with data transfer.

- The system should generate email, SMS and voice call alerts as per your preference. Also, it should be able to generate alerts to 3 to 4 operators with different type of alerts. Eg . operator 1 should get a phone call, operator 2 should get only SMS etc.

- It should be possible to see the readings of different sensors of the entire warehouse in a TV screen at a central location so that anyone can check the temperature. It is preferred if it can be the layout drawing of the warehouse superimposed with readings at a different location. SO in a single look you can see the entire warehouse plan and see all temperature readings at different locations. If any of the readings are high, it should indicate in a red colour.

- It should be cloud based server so that live data can be seen even if you are outside the warehouse over a laptop, smart phone etc. Also, if an alert comes, you can check the situation even if you are outside the warehouse and take decisions accordingly.

- If you want to get the data of your truck when it reaches your warehouse, please select a system accordingly. In such case one sensor will be fitted in the truck. When the truck goes out of the warehouse it will record the data and when the truck reaches back to the warehouse it will transfer the entire data to the centralized system. So as soon as the truck is received manual data transfer is not required.

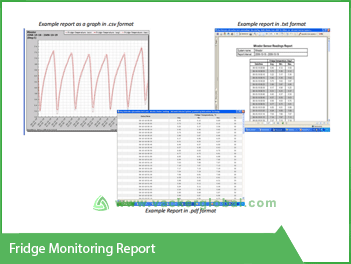

- You should be able to generate weekly, monthly reports or for any custom date range.

- You should be able to add more sensors easily without much of assistance.

Our solutions for warehouse remote monitoring

We are providing a Zigbee based temperature monitoring system which is ideally suited for warehouses and large factories. Zigbee protocol is similar to a radio frequency (Rf) system but operate in a different frequency. This basically consists of one receiver and many transmitter sensors. The sensors continuously transmit data to the receiver. The receiver will be connected to a computer or LAN network through which cloud-based monitoring and alert are generated. One receiver can receive signals from 50 to 60 sensors. The distance between a sensor and receiver can be up to 800 meters to 1 km (line of sight). However depending on the size and layout of the area, you may have to use more than one receiver.

Features:

Major features of the same briefed below:

- Each sensor has its own display on which you can see current readings. Also, critical functional parameters can be seen on this screen

- Communication distance of approximately 1 km line of sight. This means that if there is no obstruction between the receiver and the transmitter, they can communicate each other for upto 1 km.

- Phone call, email and SMS alerts can be generated in case temperature or humidity goes above or below the programmed limits. The delay period also can be programmed. If the temperature goes below 8°C for 3 minutes or below 0°C for 30 seconds, the alarm can be generated

- Alert is generated if there is communication error and also for low battery.

- Battery lasts from 8 to 10 months without recharging.